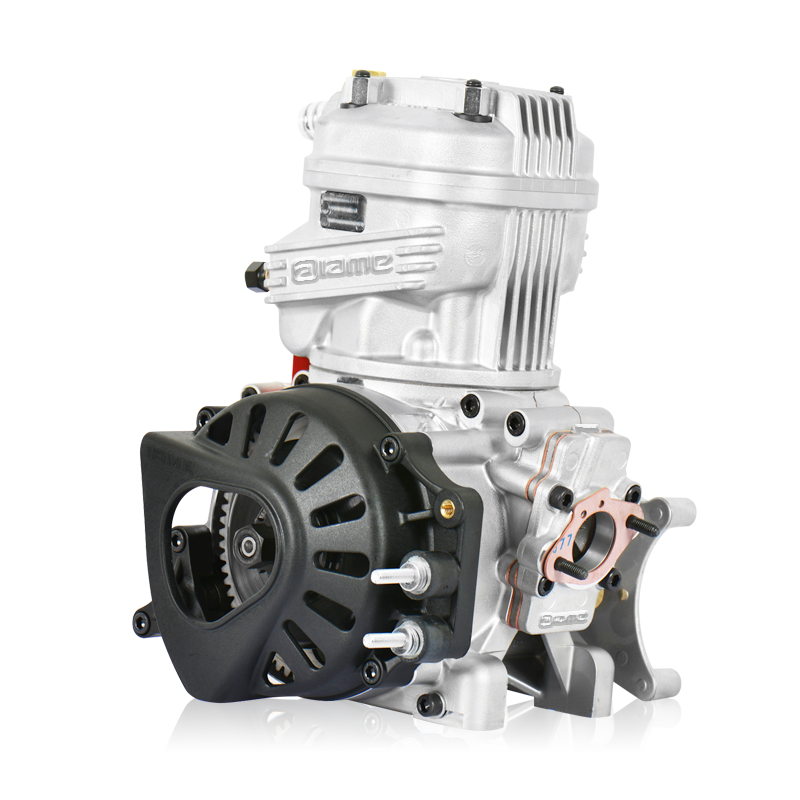

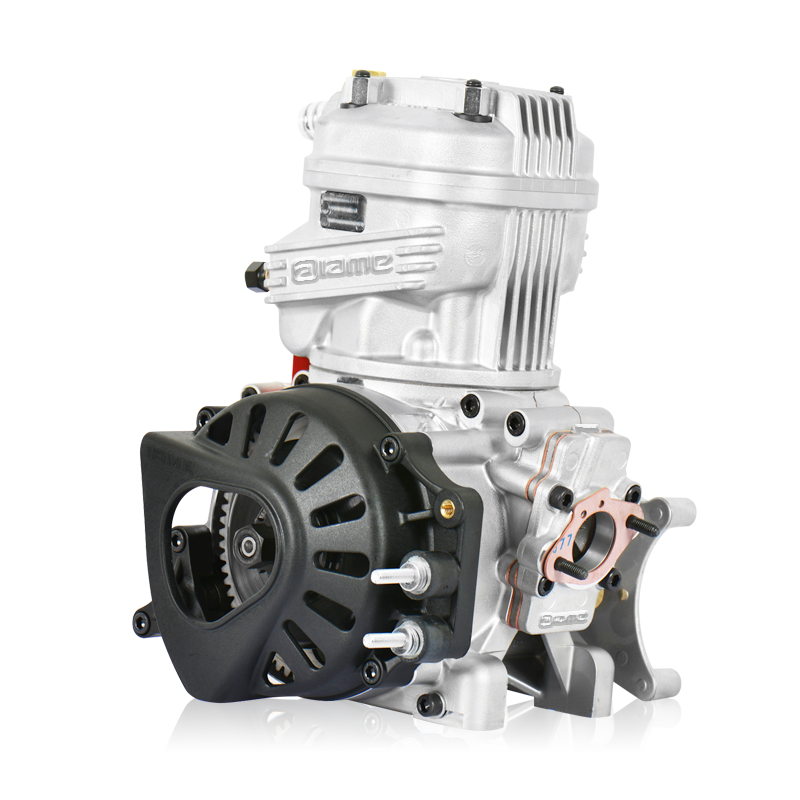

Iame X30 Junior complete engine

The best selling X30 is the most successful blend of innovation and tradition. Offering modern features such as an electric starter, balancer shaft and water-cooling, while preserving traditional specifications that include the diaphragm carburetor and the absence of the power valve. The result: an engine that is fun to drive, easy to use and long lasting. Pure karting!

Technical information

model: X30 125cc

description: Single cylinder – 2 stroke

class: 125cc Stock Class

bore: Ø 54,00mm

max-bore: Ø 54,28mm

stroke: 54,00mm

displacement: 123, 67cc

ports: 3

inlet-system: Reed Valve

lubrication: Oil mixture

ignition-system: Digital

transmission: Centrifugal Dry Clutch

cooling-system: Water

balancer-shaft: Present

starter: Electric

carb-model: Tillotson HW-27A

max-power: 30 Hp

max-torque: 19, 5 Nm

max-rpm-limit: 16.000 RPM

All the parts of the X30 engines are manufactured by latest generation numerical control machining centers, this translates into an extreme accuracy of the sensitive dimensions. IAME high quality standards guarantee the Drivers with the zeroing of any performance difference among the engines and with the absolute certainty of competing on the track on equal terms with all opponents. The X30 units are Ready To Race just like the World Champions engines, the result of decades of experience in manufacturing Karting IAME engines.

The engines of the X30 range are popular in more than 30 countries, only for some of them there are slight variations of equipment related to the specific requirements of the national sports authorities. However, at international events involving drivers from around the world using the X30 engines in one configuration, the performance differences are clearly imperceptible. Looking at the lap times of competitions such as the IAME International Final, it’s easily notable how many drivers are enclosed in the gap of ½ second. It’s only thanks to the construction quality and guaranteed constancy over the production that IAME can get such results and receive the appreciation of an undisputed success by drivers around the globe.

Thanks to the uniformity, consistency and high level of performance of all X30 engines, from the small 60cc X30 Swift Water up to the ultra high performance X30 Super Shifter, Drivers and mechanics can focus all available resources on the set up of the vehicle, the physical preparation, driving skills improvement and on the strategy to be winning over the opponents. Karting is the Motorsport discipline that comes closest to the driving sensations of the powerful F1 cars. At IAME, we want Karting to be practiced by anyone who shares our passion, that’s why we offer our Drivers performing and reliable engines, eliminating the need for costly preparations. Preserving this cardinal principle, IAME is able to offer engaging and rewarding experience to Drivers around the world, ensuring a tight budget.

Inside the box containing the emotions generators named X30, each Driver can find all the accessories needed to easily install and use the engine on their preferred chassis. Chosen carefully and after undergoing several tests, all the accessories that complement the X30 engines are designed to work at best under all conditions and ensure the correct operation and a totally fulfilling experience at all times. Thanks to the unique serial number that distinguishes each unit, each Driver can date back to the year of manufacturing of his X30 and find the original spare parts suitable for the proper maintenance, through the IAME official dealers network. Fill up the fuel tank and jump on track for your next challenge, only caring where to put your wheels!

Featuring high performance and wide rpm range together with a great drivability and ease of use, today IAME X30 is the only power unit able to boost popular Karting as well as the highest level international competitions.

-

No power valve

-

Very high power level and impressive torque diagram even without power valve

-

Essential racing design, compact dimensions, light weight

-

Controlled RPM range to increase durability and reliability

-

Water cooling for cylinder, cylinder head and back part of the crankcase. No on-board water pump

-

Direct drive for true racing experience, less complication and cost

-

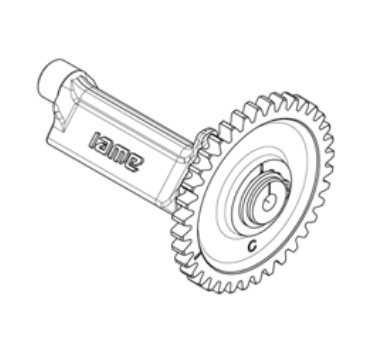

Limited vibrations by integrated balancer shaft

-

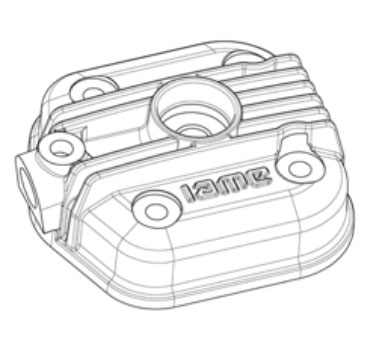

Automatic decompressor valve on the cylinder head for easier start and Kart moving when engine is off

-

Cost-effective engine design

-

Reduced maintenance in comparison with the existing Sudam engines

-

High performance consistency

Worldwide Racing Machine

Approaching the design, the challenge is to offer to the drivers a new package of performance, reliability, and lower exercise costs, compared to the current engine they use.

The bench is the 125cc Sudam, being the most simple and performing two stroke engine for Karting still produced.

The difficulty is not to increase mechanical complexity while providing the Sudam a worthy companion and successor.

Keeping into account three main technical points:

1- to avoid the power valve, possible source of problems and basically unknown by the target users,

2- to reduce the maximum rpm to 15.000, to increase durability

3- to guarantee a really exciting performance level,

we took the decision to increase the displacement to 175cc.

In order to maintain the crankshaft compact and light, we increased only the bore to 64mm, leaving the stroke at 54.4mm.

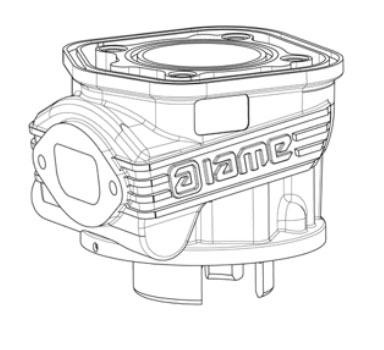

The cylinder, is made by gravity casting in high-strength aluminum alloy, with adequately dimensioned water jacket.

The cylinder is provided with cast iron liner, manufactured in IAME by precision 5-axis CNC machines. The tight manufacturing tolerances guarantee the consistency of performance throughout the production.

The cylinder head is made by gravity casting as for the cylinder. The combustion chamber is machined by CNC precise machining.

The water jacket in both cylinder and cylinder head allow an equable cooling on all the surfaces.

The gear-driven balance shaft is there to reduce vibrations and it’s placed in the rear of the crankcase. It is composed by the driving gear on the engine left, and the balance element placed in the center of the engine. All the components are in high strength casehardened steel. The teeth of both driving and driven gears are precisely grinded for smoother contact and great reliability.

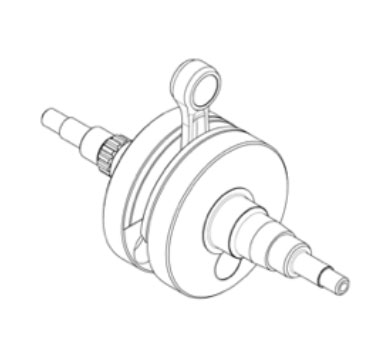

The crankshaft is composed type, with 20mm crankpin and big 30mm journals for the best durability.

Both crankshaft and crankpin are made by forged steel, casehardened and grinded.

The conrod, completely CNC machined from forged steel, has very robust “double-T” body. It’s supported by precision roller cages on both ends. The conrod design has been refined throughout years of experience.

The main bearings are largely dimensioned.

The piston is casted with a particular high-silicon alloy. It is a typical two stroke design with one “L” ring, chromium plated

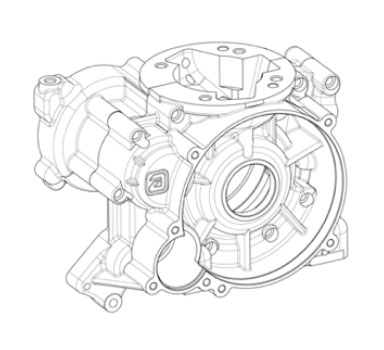

Crankcase and gear cover are built by gravity casting allowing the best material characteristics. Stable and light.

The transmission is provided with centrifugal dry clutch to allow the electric starter and the typical Touch and Go ease of use.

The ignition is digital. The small inertia of the internal rotor reduces solicitations on the crankshaft and allow lighter engine weight. The inaccessible digital programming provides the rev. limitation. The electronics are in the coil.